Reinert-Ritz GmbH develops innovative products made of thermoplastic material. The result of the experience gained in this way are moulded parts that are not available on the market as standard in these sizes. In addition to their size, these products convince more and more new customers worldwide with their quality and safety. With its many years of experience, seamless quality assurance and high production quality, Reinert-Ritz was also able to convince the planners of this major project.

Case study: The world’s most challenging PE 100 RC project to date – floating drinking water pipeline in the Mediterranean Sea

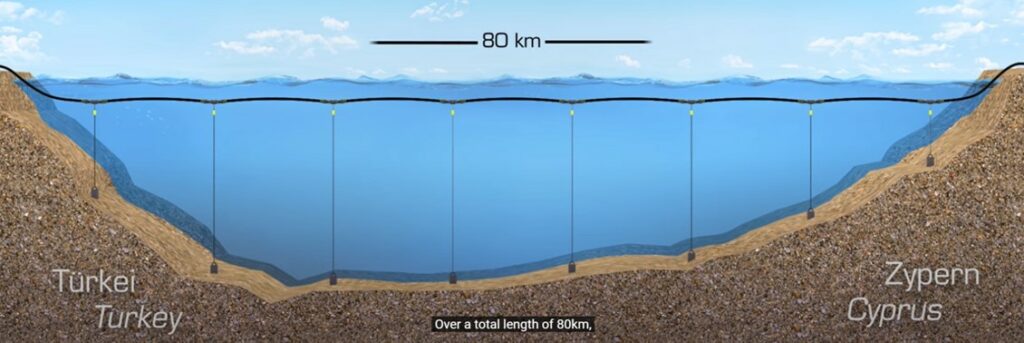

With the construction of an 80km long pipe system through the waters of the Mediterranean, a new standard has been set in water distribution. The urgently required water supply for Northern Cyprus comes from a reservoir near to the Turkish coastline. From there the pipeline goes directly to the coast and then through the Mediterranean to the Turkish part of the island of Cyprus.

The solution: Floating PE 100 pipes held by steel cables

Over a total length of 80km, 500m lengths of 1,6m diameter pipe are coupled together and anchored to the seabed by means of wire cables. In order to link the sections of pipe a special connector piece is required in polyethylene (PE100). The challenge consists of the safe and durable connector elements which link the PE pipe with the steel bends, such that the tethered pipe system remains at a depth of 250m in the most adverse of conditions.

Safe PE 100 solutions for demanding users worldwide

For over 40 years, Reinert-Ritz GmbH, in the town of Nordhorn, Lower Saxony, Germany, have developed innovative products from thermoplastics. The results of the experience thus gained are fittings, which are not available as standard on the market in these dimensions. New customers worldwide are always persuaded by the qualitative nature of these large dimension products. With their years of experience, complete quality assurance and manufacturing excellence, Reinert-Ritz were able to convince the planners of this major project of their capabilities and their capacity.

Before the raw material supplier may discharge the 25 tons of PE granules into the silos of the company, a sample is taken from the delivery and examined in the laboratory by the factory quality assurance staff. The granulate sample is tested under strict guidelines using established test methods. This complete quality assurance is a permanent feature in the Reinert-Ritz GmbH manufacturing process. Only when the sample meets the high standards of the company, may the granulate be processed further.

In the adjacent extrusion department, semi-finished products up to 2000mm diameter and more are produced from the granulate. Here the granulate is fed directly into the so-called extruder the Structure of which is similar to that of a meat grinder. The granules are introduced via a hopper and moved by a screw conveyor through a heating zone. With the influence of friction, temperature and increasing pressure, the loose granulate grains are melted. The now plastically deformable mass is forced through a system developed by Reinert-Ritz such that a thick-walled plastic semi-finished product is formed. As soon as the very hot and even deformable semi-finished product leaves the die, it must be cooled. Coupled directly to machine is a cooling pool where the heat is dissipated. At the end of the extrusion line, the dimensionally stable semi-finished product is cut in the length required by the customer. Even the semi-finished product is monitored by the Quality Assurance. From each hollow bar and solid rod produced at Reinert-Ritz a sample is taken. As with the original material, the granules, the semi-finished product samples are tested for their properties in the laboratory.

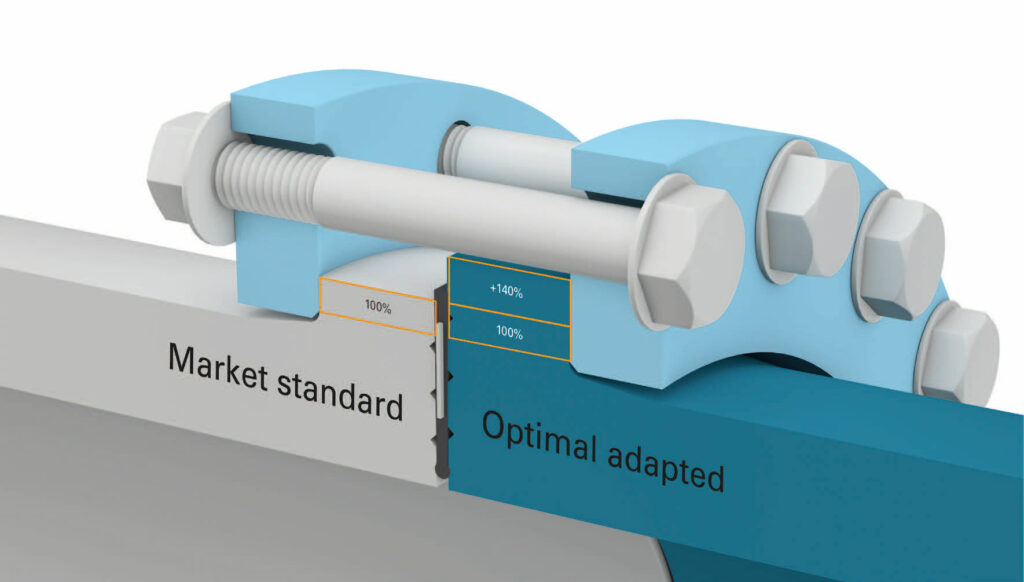

After release by quality control the semi-finished product can be used to manufacture the finished product in subsequent processing steps. In order to process the thick-walled semi-finished products into the required finished products for the customers, the family concern Reinert-Ritz has a large and modern machine park. With the use of computer-controlled lathes and milling machines – from small to very large semi-finished products – everything can be processed efficiently and with the best quality. The special stub ends for the Turkey project were created using a special portal milling machine. This can be used to process semi-finished material to a diameter of 2m without problems. Despite these dimensions, the milling machine operates with a very high accuracy. For the fitting, which is used in this drinking-water project this dimensional stability is particularly important because the fittings are used within the transition from PE100 to the pre-formed steel bends. Therefore, each component manufactured by Reinert-Ritz for this major project has to meet the very small specified tolerances.

And for quality assurance each is provided with a unique and permanent identification Finally checked and packaged, the fittings are transported to Turkey by truck.

To date over 300 of these fittings have been manufactured and installed successfully for the TRNC project. Every day fittings are sent from Nordhorn to over 40 countries around the world.

About the author

UP TO DATE

Subscripe to our newsletter.

More topics

Related articles

Our comment: latest ISO 9624 is faulty and causes unnecessary problems for users of thermoplastic flange connections.

In Glattfelden, a problem with deposits in the pipes has arisen. Patrick Frei, the municipality’s wastewater treatment supervisor in charge, decided to clean the pressure pipe and relies on the gentle pigging process. The biggest problem with pigging is that the pig has to be inserted into the pipeline, which means that the existing pipeline has to be dismantled and opened. This is a laborious process, which Frei was able to improve significantly with the Quick-Pig pig trap.

Pigging a pipeline must become easier and safer! Without a complex manhole, without time-consuming ventilation of the manhole, directly from the street, made of PE 100 and corrosion-free. With these requirements, Hamburg’s municipal drainage system (now Hamburg Wasser) approached Reinert-Ritz GmbH from Nordhorn. The fittings manufacturer developed a station that enables fast, safe pigging without a manhole and has been used successfully in various projects to date.