Find the right PE 100 or PP flange connection for your application! The Flange Selection Guide is a guide to help you find the right flange connection for your application. Standard backing flange and welding neck flange connections present some challenges: They are unstable, prone to failure and critical in connecting to other materials. With the flange selection guide, you can quickly find the right flange connection for your application:

PE / PP Flange Selection Guide

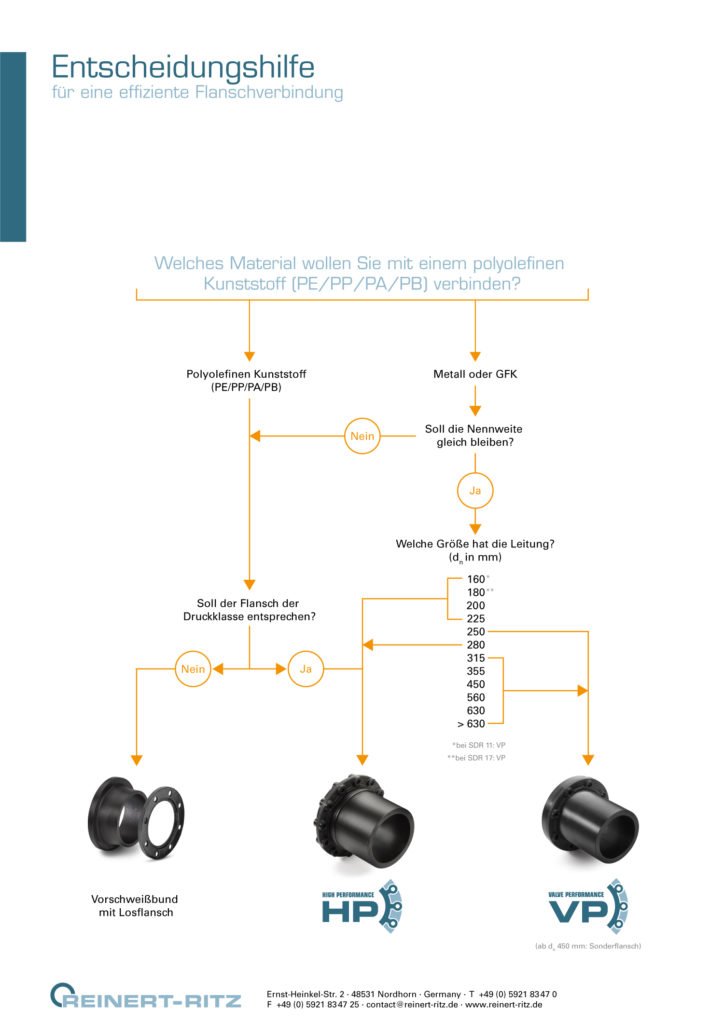

Learn in this guide which PE/PP flange is the best choice for your application. Standard stub-ends in PE and PP pressure piping systems often cause problems. Therefore, Reinert-Ritz has developed various solutions to reliably create flange connections. In this selection guide, you will learn:

Leakage and nominal size offset: Problems with standard plastic stub-ends

Problems with plastic piping? Reinert-Ritz has the solution! The first plastic pipes, PE (HD-PE) and PP, emerged, and the connection dimensions for standard stub-ends from metallic pipelines were adopted. However, this led to two problems: the internal offset between plastic and steel/cast/GFRP pipes, especially with fittings, and insufficient stability under various loads. Reinert-Ritz has addressed these problems, resulting in solutions for both: the special flange VP for the internal offset problem and the HP flange for the stability problem. Learn more about the history of flange connections and how we developed our problem-solving solutions in our article by Michael Stichternath.

Find the appropriate solutions now and improve your plastic piping!

Selection process for plastic flanges: Creating optimal and reliable PE/PP flange connections

- Check internal offset

In the following section, you will find a simple tool to determine if the special flange VP can be used to minimize the internal diameter offset. If so, the special flange VP is the best choice. Wenn ja, dann ist der Sonderflansch VP die beste Wahl.

– - Assess load and load-bearing capacity

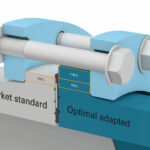

Evaluate whether the standard PE 100 / PP standard stub-end provides sufficient reserves for the loads in your application. If you are uncertain, the HP flange, as a plastic-compatible and fully load-bearing PE 100 / PP loose flange, is the optimal choice.

We are happy to assist you in selecting the appropriate flange for your application.

Find the right PE 100/PP flange for connecting to metallic pipelines

PE 100 and PP pressure pipes are commonly used in many utility networks and industrial plants to transport liquids or gases. The pipes are typically equipped with standard stub-ends that are attached to metallic flanges such as fittings. However, this construction often encounters problems that can lead to leaks. The root cause of these problems is the difference in internal diameters between many PE/PP pipe dimensions and the DN-oriented steel/cast or GFRP pipes. As a simple solution, standard stub-ends are given a bevel on the construction site. Typically, they are roughly processed with an angle grinder, which makes the collars unstable and can result in leaks. To avoid these problems, it is important to select the correct flanges during the planning phase. The solution for connecting PE 100/PP pipes to fittings, steel, cast, and GFRP flanges is the special flange VP:

- Cost-efficient

The VP flange allows you to integrate fittings cost-effectively. - Installation

he installation is straightforward, and the flanges are available in various sizes. - Higher stability

VP flanges offer higher stability compared to conventional flanges. - Minimal offset

Additionally, they have improved flow properties and reduced deposits.

In this video, you will learn about the many advantages of the special flange VP compared to the PE 100/PP standard stub-end:

To determine if the special flange VP is the right choice for your application, you can use our flange finder. Simply adjust the appropriate pipe diameter for your application (e.g., DN/od 160) and read the optimal DN/flange combination on the left and right: Set pipe size DN 150 SDR 17/11* ∅ 160 DN 125 SDR 11 HP flange View product Special flange VP View product

Do you have an application that doesn’t match our tool? Then describe your application to us here. We will assist you in selecting the correct flanges.

Join many of our customers in making the special flange VP your standard choice for connecting to fittings. Inquire now!

PE 100/PP standard stub-ends: When is the standard stub-end the right choice for your pressure piping?

Designers and users of standard plastic standard stub-ends are familiar with the problem. They are often challenging to seal during assembly, and leaks occur at flange connections throughout the lifespan of the PE/PP pressure pipeline. Some flange dimensions are easily sealed, while others require a delicate touch, and some are highly critical. Standard stub-ends are not designed to be compatible with plastics; the plastic is overloaded, leading to deformation over time. Environmental conditions also influence the tightness of the connection, with extreme cold or heat further complicating the assembly. The result is costly maintenance and repair measures, as well as production downtime.

The typical problems with PE 100 and PP standard stub-ends are:

❗️ Standard plastic standard stub-ends are often challenging to seal.

❗️ Leaks frequently occur at flange connections during the lifespan of the PE/PP pressure pipeline.

❗️ Standard stub-ends are not designed to be compatible with plastics, leading to plastic overloading and deformation over time.

Flanges must be mountable reliably, even under challenging conditions. Therefore, they need sufficient reserves against overload, regardless of whether the overload arises from pressure, environmental influences, or during assembly.

Standard stub-end checklist!

Many customers are unsure whether they can use PE 100/PP collars for their applications. Positive and negative experiences with standard stub-ends often mix. Additionally, the decision impacts the quality of the pressure pipeline. We have created a checklist for our customers. Using the checklist, you can assess the criticality of your application. If in doubt, it is better to use the reliable HP flange.

Test our checklist now and decide if standard stub-ends are suitable for your application:

Standard stub-ends should be assessed critically in the following situations:

- Deviations from the usual pressure ratings:

Greater than PN 10 is generally critical. - Large pipe diameters

Diameters larger than DN/od 500 (flange size DN 500) are challenging during assembly - Applications with additional loads

Freely laid pressure pipelines, bending stresses, temperature effects are critical applications for the standard standard stub-end. - Critical applications

Critical applications where failures can lead to significant damage must be given special attention. - Inexperienced installers

Inexperienced or untrained installers can also pose a problem.

Whether you want to use an HP flange or standard stub-end, feel free to inquire directly with us:

If you are unsure about the correct flange connection for your needs or if you would like to avoid a flange connection but lack a solution, we are here to help. In addition to many reliable flange solutions, we also have decades of experience in flange-free transitions and connector systems. We will be happy to advise you. In addition to many reliable flange solutions, we also have decades of experience in flange-free transitions and plug-in connections.

About the author

UP TO DATE

Subscripe to our newsletter.

More topics

Related articles

Our comment: latest ISO 9624 is faulty and causes unnecessary problems for users of thermoplastic flange connections.

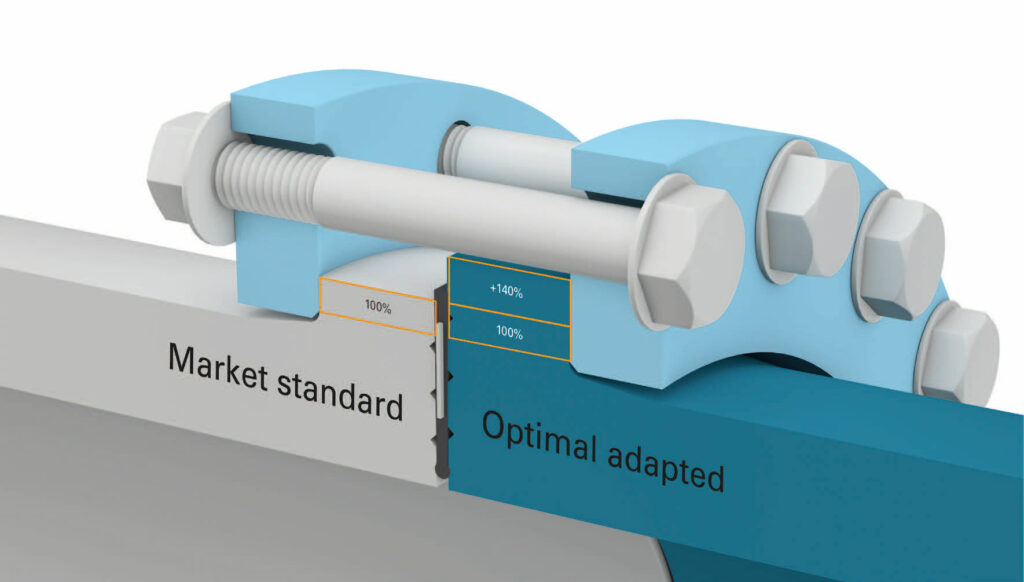

Reinert-Ritz GmbH develops innovative products made of thermoplastic material. The result of the experience gained in this way are moulded parts that are not available on the market as standard in these sizes. In addition to their size, these products convince more and more new customers worldwide with their quality and safety. With its many years of experience, seamless quality assurance and high production quality, Reinert-Ritz was also able to convince the planners of this major project.